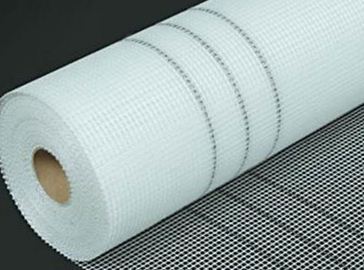

Fiber Mesh

MOQ : 4 Rolls

Fiber Mesh Specification

- Coating Type

- Acrylic or PVC coating

- Glass Type

- E-glass

- GSM

- 45-160 GSM

- Shape

- Roll

- Temperature

- Up to 550C

- Usage & Applications

- Strengthening cement, tile, marble, and other building materials

- Thermal Conductivity

- Low

- Thickness

- 0.2 mm - 1 mm

- Density

- 200 Gram per cubic centimeter(g/cm3)

- Material

- Glass Fiber

- Application

- Wall reinforcing, Construction, Waterproofing, Crack resistance

- Technique

- Woven

- Surface Treatment

- Alkali Resistant

- Dimension (L*W*H)

- Custom sizes available

- Weave Type

- Plain

- Tensile Strength

- High

- Adhesion

- Strong bonding with substrates

- Packaging Type

- Rolls with poly bag or carton packing

- Length Range

- 50 m - 300 m

- Moisture Resistance

- Excellent

- Color

- White, Yellow, Blue, or as required

- Fire Resistance

- Non-combustible

- Shelf Life

- Unlimited under proper storage

- Width Range

- 10 cm - 200 cm

- Elongation at Break

- < 3%

Fiber Mesh Trade Information

- Minimum Order Quantity

- 4 Rolls

- Payment Terms

- Telegraphic Transfer (T/T), Cash in Advance (CID), Cheque, Cash Advance (CA)

- Delivery Time

- 7 Days

- Sample Available

- Yes

- Sample Policy

- Free samples are available

- Packaging Details

- 50 Mtr. in 1 Roll

- Main Domestic Market

- All India

About Fiber Mesh

Properties of fiber glass mesh after surface treatment are as follows:

- Water resistance

- Alkali resistance

- Flexible

- Soft

- Resistant to ageing

Application Areas:

- Wall enhancement

- Wall thermal insulation

- Water proofing

- Various fiber glass wares such as polyphony boards, anti-corrosive boards, plaster boards, heated boards, marbles and mosaics, & exterior insulation

Salient Features:

- Durable

- Versatile

- Cost effective

- Easy to handle

- Good resistant to all the adverse climatic conditions

Superior Strength and Versatility

Engineered from premium E-glass fibers, our fiber mesh offers exceptional tensile strength and outstanding adhesion to various substrates. Its plain weave and alkali-resistant surface treatment guarantee durability during wall reinforcement, waterproofing, and other construction applications. The acrylic or PVC coating provides additional versatility for different project needs.

Customizable for Every Project

We supply fiber mesh in various dimensions and colors to match specific project demands. From widths of 10 cm to 200 cm and lengths up to 300 m, customers can choose custom roll sizes suitable for wall reinforcing, crack control, or crack resistance in cement, tile, or marble installations. Our density and thickness options support both lightweight and heavy-duty applications.

FAQs of Fiber Mesh:

Q: How is fiber mesh typically used in construction projects?

A: Fiber mesh is commonly embedded within walls, floors, or waterproofing systems to enhance structural integrity, prevent cracks, and increase resistance to moisture. It is compatible with cement, tile, marble, and other building materials, facilitating long-lasting reinforcement.Q: What makes this fiber mesh suitable for high-temperature environments?

A: Made from E-glass fiber, this mesh can withstand temperatures up to 550C without degradation. Its non-combustible nature ensures reliable performance in fire-prone areas or intensive industrial applications.Q: When should fiber mesh be applied during the construction process?

A: Fiber mesh is best installed during the substrate preparation phasebefore final surfacing or plastering. This ensures strong adhesion and effective reinforcement as part of the base system for walls, floors, or waterproofed structures.Q: Where can I use this fiber mesh for optimal results?

A: It is ideal for use in wall reinforcement, waterproofing, flooring underlays, and areas prone to cracking such as corners, joints, and angles in cement, tile, or marble applications.Q: What benefits does fiber mesh offer compared to traditional reinforcing materials?

A: Fiber mesh provides higher tensile strength, excellent moisture resistance, low thermal conductivity, and superior crack prevention. Its alkali-resistant and fireproof properties outlast traditional metal mesh, reducing long-term maintenance.Q: How is the fiber mesh packaged and stored?

A: The mesh is supplied in roll form, securely packed in poly bags or cartons. With proper storage, it maintains its properties indefinitely, ensuring an unlimited shelf life for future use.Q: What process is involved in installing fiber mesh?

A: Installation involves unrolling the mesh, cutting it to the required size, and embedding it within the chosen substrate (e.g., cement or plaster) using standard application techniques. It bonds well due to its strong adhesion and alkali-resistant coating.

Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

More Products in Fiber Glass Mesh Category

Fiberglass Filtration Mesh

Price 12 INR

Minimum Order Quantity : 30 Square Meters

Material : Fiberglass

Fibre Glass Mesh 110 GSM

Price 19 INR / Square Meter

Minimum Order Quantity : 400 Square Meters

Material : Glass Fiber

Send Inquiry

Send Inquiry