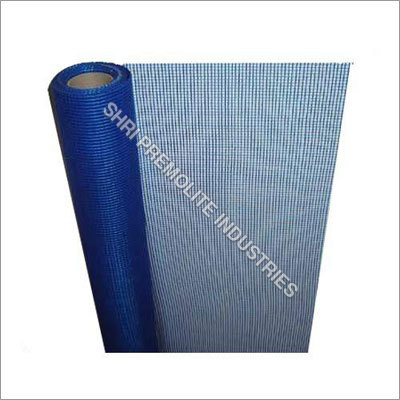

Thermal Insulation Fiberglass

Price 90 INR/ Square Meter

MOQ : 400 Square Meters

Thermal Insulation Fiberglass Specification

- Density

- 96 Gram per cubic centimeter(g/cm3)

- Thermal Conductivity

- 0.035-0.045 W/mK

- Temperature

- -200C to +550C continuous use

- Coating Type

- Aluminum Foil coated or uncoated

- Glass Type

- E-glass

- Usage & Applications

- Construction, HVAC, industrial insulation, fire retardant barriers

- Thickness

- 25 mm, 50 mm, or as requested

- Shape

- Roll, Slab, Board, Pipe Section

- GSM

- 90-1600 GSM, depending on type

- Material

- Glass Fiber

- Application

- Thermal Insulation in buildings, ducts, piping, roofing, and industrial equipment

- Technique

- Woven with advanced fiberglass weaving technology

- Surface Treatment

- Aluminum foil or plain finish

- Dimension (L*W*H)

- Standard 1.2m width, length customizable, thickness as specified

- Lifespan

- 50+ years under normal conditions

- Water Resistance

- Excellent, does not absorb water

- Color

- White/Yellow (natural fiberglass color)

- Tensile Strength

- High, typically 400-900 MPa

- Corrosion Resistance

- Inert to most chemicals and does not corrode

- Fire Rating

- Class A/1 non-combustible (as per ASTM E84/EN standards)

- Sound Absorption Coefficient

- Up to 1.05 NRC at certain frequencies

- Packaging

- PE bags or cartons, custom packaging available

- Moisture Absorption

- <1% by weight

Thermal Insulation Fiberglass Trade Information

- Minimum Order Quantity

- 400 Square Meters

- Payment Terms

- Telegraphic Transfer (T/T), Cash in Advance (CID), Cheque, Cash Advance (CA)

- Delivery Time

- 7 Days

- Sample Available

- Yes

- Sample Policy

- Free samples are available

- Packaging Details

- 50 Mtr. 1 roll

- Main Domestic Market

- All India

About Thermal Insulation Fiberglass

We are counted amongst the top manufacturers, traders and suppliers of supreme quality Thermal Insulation Fiberglass Mesh. This is coated using acrylic polymer and is woven using textile glass. It is a strengthening material for wall, GRC wallboard and internal and external temperature preservation panel. Appreciated for the low-co-efficient of thermal expansion, non-combustibility, electrical and high heat resistance properties; this is available in different dimensions as per the application needs. We offer this product to our clients at industry leading prices.

It finds applications in:

- Power plants

- Hot/cold pipes

- Warehouses

- Ducts abroad ships

- Air conditioning plants and other industrial purposes

Exceptional Fire and Moisture Resistance

The fiberglass insulation is classified as Class A/1 non-combustible under global standards (ASTM E84/EN), offering critical safety in fire-prone environments. Its sub-1% moisture absorption and outstanding water resistance ensure sustained performance even in humid or damp conditions, preventing material degradation over decades of use.

Versatile Applications and High Performance

With a thermal conductivity of 0.0350.045 W/mK and high sound absorption (NRC up to 1.05), this material excels in multiple settingsconstruction, HVAC duct insulation, industrial plant piping, and fire retardant barriers. Engineered with robust E-glass fibers, it supports continuous use from -200C to +550C and is available in diverse forms, thicknesses, and coatings to fit specific project needs.

Customization and Eco-Friendly Packaging Solutions

Dimensions, thickness, and coatings (plain or aluminum foil) can be tailored to any requirement. Packaging is offered in PE bags or cartons, with custom solutions to facilitate handling, transport, and installation for domestic and international clients. Its inert composition resists most chemicals, ensuring long-lasting, maintenance-free performance.

FAQs of Thermal Insulation Fiberglass:

Q: How is thermal insulation fiberglass installed in building or industrial applications?

A: Thermal insulation fiberglass is supplied as rolls, slabs, boards, or pipe sections, offering flexible installation options for walls, roofs, piping, and ducts. The material can be cut to size and fitted within cavities or around equipment, often secured with fasteners or adhesives and finished with a plain or aluminum foil surface as required.Q: What are the main benefits of using fiberglass insulation with less than 1% moisture absorption?

A: Fiberglass insulation with moisture absorption below 1% resists water infiltration and prevents the growth of mold, maintaining its insulative and structural properties for decades. This enhances reliability in humid, damp, or exposed environments, ensuring long-term efficiency and minimal maintenance.Q: When is fiberglass insulation with Class A/1 fire rating recommended?

A: Fiberglass insulation with a Class A/1 fire rating is ideal for use in areas where fire safety is paramount, such as commercial buildings, industrial plants, and fire barriers. The product meets stringent ASTM E84/EN standards for minimal combustibility, limiting fire spread and improving occupant and asset protection.Q: Where can this thermal insulation fiberglass be applied for optimal performance?

A: This insulation is used in a variety of applications, including building walls and roofs, HVAC ducts, process plant piping, and industrial equipment. Its high temperature tolerance (-200C to +550C) and chemical inertness make it suitable for both residential and demanding industrial settings.Q: What is the process for customizing dimensions or coatings for specific projects?

A: Customers can request tailored lengths, widths, thicknesses (25 mm, 50 mm, or custom), and surface treatments (plain or aluminum foil). Upon specification, the manufacturer weaves, cuts, and packs the fiberglass insulation accordingly, ensuring it meets the technical and aesthetic requirements of each application.Q: How does the sound absorption capability benefit building environments?

A: With a sound absorption coefficient up to 1.05 NRC, this fiberglass significantly reduces noise transmission for improved acoustics. It is especially valuable in offices, schools, and hospitals, or anywhere controlling sound levels enhances comfort and productivity.

Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

Send Inquiry

Send Inquiry